Bedrock – Wood – Part 2

Wood

Wood is the second in a four-part series about the bedrock upon which Duration is built. Elements of Water, Wood, Metal and Stone reveal the pioneering technology built into our foundations to stay true to our ethos of ‘beers that belong’. Read on to learn how our sense of place informs all we do.

In our last post on Water we talked about being early adopters of new water technologies. Treating inbound water to improve our beer water profiles and reducing our outbound water – both as a pollutant and in terms of consumption – through recycling and reusing it as rinse water.

This post on Wood covers the ‘wild’ side of our production – slower inoculated beers made from spontaneous yeasts that play out over months, if not years to deliver new powerful flavour complexity and depth of character. Beers that often go on to be rested on wood absorbing further flavour from the specific wood used, how it is toasted and steamed and what cultures and bacterium lives within it.

Slow beer is made at an entirely different tempo to fast beers and something we are keen to focus on. Here we discuss the specifics of the 3 x 17HL vessels made we have had custom made by Foeder Crafters of America (we are their first UK installation) and the coolship we have designed – made by 6ix Fab Dec.

Photo gallery info/credits:

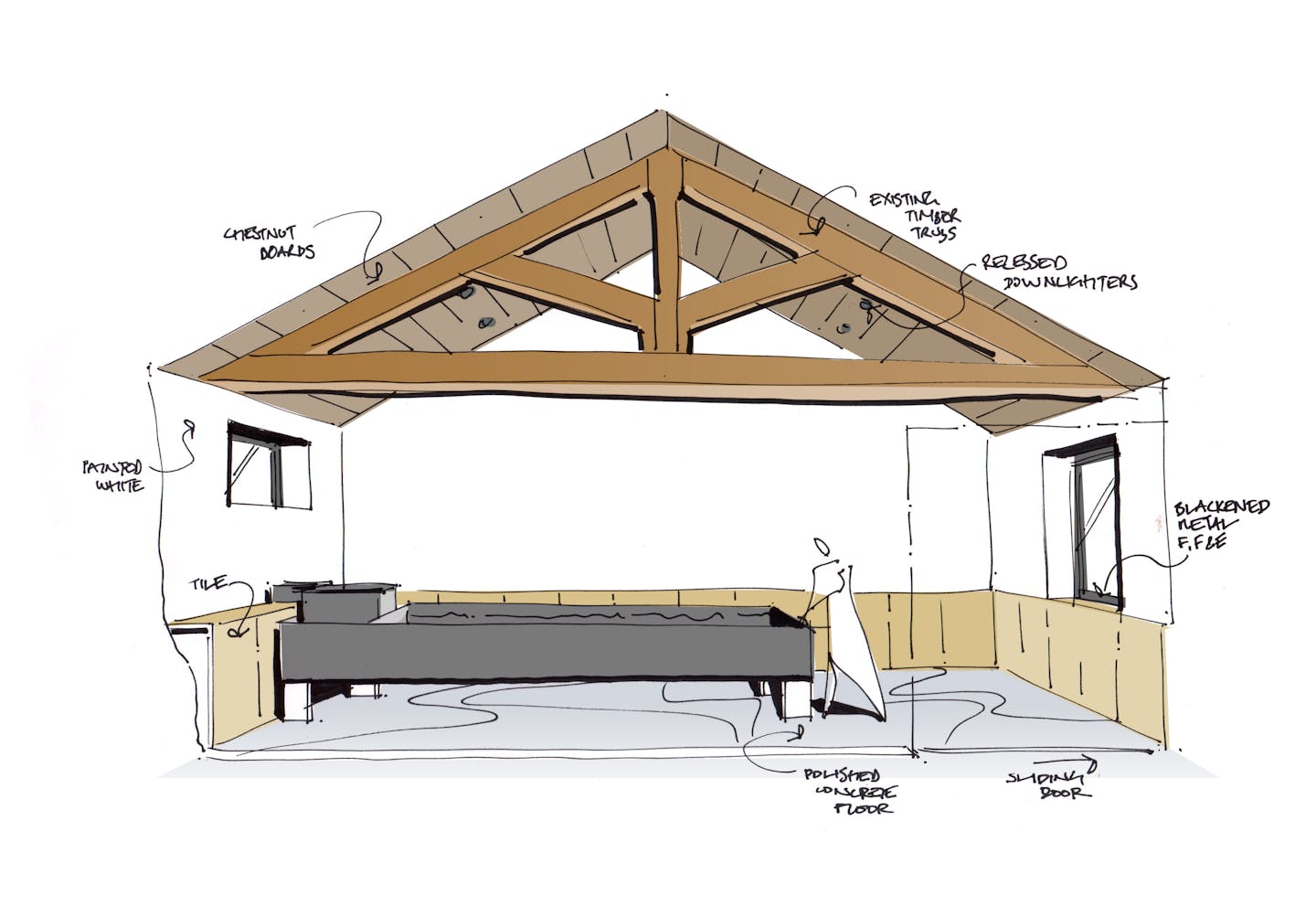

1) Coolship Sketch: 5HT, 2) Simon James, 3) Estate Chestnut Boards on the Coolship ceiling, 4) wood division during restoration, 5) wood division complete pre installing coolship and foeders

Our brewery name actually plays to making both the fast fresh, clean beers we love and slower, wild beers we adore. We picked our name based on our desire to explore creative processes in beer.

In musical terms ‘Duration’ is the distance between two beats, a space, a pause – this connects to fast and slow beer, and it alludes to beers journey through time and place. In philosophical terms in Elon Vital is a concept of Henri Bergson. He contested, all living things strive creatively to reinvent themselves. They evolve in order to remain relevant.

We don’t intend for our beers to ever stand still or reach a finished point. Instead we want each beer we make to undulates like a living entity that is under continual improvement. We see our work as a brewer to stay dynamic and responsive and to progress beer styles as they evolve on their journey.

Bates, our brewer is an epicurean that has brewed and cooked commercially in the US and the UK for the past two decades.

From the deep south where rugged and hardened customs prevail and where people feel they are intrinsically bound to their land. ‘Knarly’ is a mindset and outliers are revered – as such we draws inspiration hugely from nature and survival and absolutely loves the idea of wild beer. As an avid reader, chef and brewer we hugely values the table offering as the truest expression of any civilisation. Bourdain was a huge inspiration to him for shining a light on what coming together to break bread can mean as a universal truth across borders and cultures.

Obsessed by flavour and taste and keen to see good farm to table practises appreciated. He wishes to work in a creative way that is respectful to the harvest of the land, and to advance flavour combinations and thus the popularity of yeast forward beers. When we think of the dimensions of complexity in a sour beer, Bates is thinking about what is happening scientifically at a molecular level to enhance flavour and to bring the same attention to detail and discipline to wild production that clean brewing is afforded. The result we hope will be perfectly balanced wild beers with amazing depth of character.

Photo credit: Bates in Chicago by Bob Gigliotti

So, let’s get straight to it and see what Bates has put into his wood division, in his own words:

Foeders

Foeders have been a method used for fermenting beer long before stainless. Large wood barrels were the norm for vatted porters and English IPA’s of old. Now primary fermentation is more commonly takes place in stainless, transferring to wood to age the beer. Wood imparts flavour or can be used to inoculate mixed fermentation beers with various introduced or local cultures, often living in the wood.

Matt one of the founders at Foeder Crafters in St Louis, USA has a deep appreciation and understanding of woodworking. Taking it’s long history and applying his skill with new thinking to address a gap in the market. The way he is combining traditional techniques with updated technology blew my mind. Take gastronomy and where cuisine is today, it’s taking us to the next level of taste and product presentation on top of the added historical context of cuisine. It fascinates me. What Matt and the guys at Foeder Crafters are doing for beer is a kin to what modern chefs are doing for food. The benefit to the end product is exponential. Understand product development and that the resulting drinker experience is key.

Foder Crafters – Photo Credit: Beer Advocate

Our 3 x 17HL horizontal American white oak foeders (for starters) can be utilised a myriad of ways. Sized for smaller batches of the most experimental styles in our offering and seasoned each for specific use. I added customised top ports and internal plate chillers too. Why let a barrel go in and out with the seasons if you know where the beer will be happiest? Why wouldn’t you want put it there and help it out, less vessel time = less rent to pay too right? Perhaps the most fascinating thing I admire about Foeder Crafters is the machine engineered dual-locking grooved staves. These precision cut staves interlink in a way that allow the vessels to ‘breath’ without ever leaking, or allowing additional Co2 ingress.

Let’s break all this down piece by piece.

Seasoning

Each foeder has been seasoned with steam or by being toasted on the inside to enhance flavour profiles. Starting with 3 foeders here’s what we went for.

Foeder 1 – no toast, heavy steam

This will allow for making very nuanced and low oak tannin/characteristics. Heavy steam will basically “blanch” the oak in a way making it a much softer and just a background of oak. Having no toast will keep the body and flavours light (think chardonnay-light oak flavours vs. Bourbon-heavily toasted and loads of vanilla, char, sometimes honey/brown sugar notes. This would be great for wood-aged lagers, delicate Saisons/Grisettes

Foeder 2 – light toast, heavy steam

Heavy steam gives the same as above, the light toast can add a bonus bass note, a little bit of honey and char-think for beers like a Marzen (toasty sort of lager) or Biere De Garde, or even bigger beers like barleywines

Foeder 3 – heavy toast light steam

This is essentially a big old bourbon barrel at this point. All the oak is still there, no steam bleaching, loads of char and roastiness, vanilla, honey and chewiness. This one is made for the stouts, the Dunkel’s, hell maybe even at some point a red grape/roast beer hybrid.

Top Ports

Adding top ports simply makes it easy to allow additions without a large manway opening with an unhealthy ingress of oxygen. Even though some of the beers coming out of the foeders may be mixed fermentation I’ve never been able to understand why some folks think these styles of beer are deemed “bullet-proof” to oxygen pickup. Why would you have any lower standards to than with “fresh beer” production?

Plate Chillers

Stainless chilling plates inside each vessel provides cold temperature control and allows us to make lagers in wood. Much like lagers would have been made hundreds of years ago only instead of a cold cellar or cave the chill from the inside out. This also means we can pull double time and crash cool beers letting us crop our yeast/bacterium in an easier healthier manner for the yeast and bugs. Being horizontal gives us a lower osmotic pressure – lager yeast and often lots of brett strains love this lower pressure on their cell walls, it makes for a happier healthier fermentation without stress.

Matt and Justin Founders at Foeder Crafters – photo credit: Beer Advocate

Grooved Staves

All three foeders have grooved machine cut staves held in place by bands of 95% stainless and 5% nickel. At first glance, this seems like no big deal, but what Matt at Foeder Crafters is doing here is remarkable engineering. He’s designed a dual locking system in the cut of each interlocking groove that allows for movement during the fermentation process. The vessels have room to “breath”. When any fermentation takes place in the foeder the grooves let the wood swell outwards. As it swells the groove locks in the joints allowing meaning no leaks or extra O2 can permeate. At the end of any fermentation the wood can drawback in. The grooves work like interlinked knuckles, only in the opposite direction with the same locking mechanism afforded by the joint to prevent leaks and any O2 to permeate.

The genius does not stop there; the metal blend in the bands support the breathing like a supportive ribcage to the wooden lungs – stainless is incredibly strong and sanitary, the small amount of nickel allows flex out, but retains its memory and draws the banding back in to place as the wood settles back down.

The machined grooves in the ‘breathing out’ position

I truly felt with Matt I’d found a kindred spirit. Doing what he loves, applying his skills and wisdom to just making each product count. After only an email and a call, they took me to lunch, chatted the breeze showed me their Foeders and we ended up spending the whole evening and long into the night together opening bottles of some of the best mixed-ferm beers in the world at Side Project brewing (Foeder Crafters first client). When asked for a comment from Matt for this article he wrote

‘I think it is exciting to get some of our foeders into the UK, but mostly I enjoyed drinking with Bates and chatting life and beer. I would send him a foeder no matter where he was in the world and I’m excited to see the results’

– Matt Walters, Co-Founder and Master Cooper, Founder Crafters of America

Coolship

Koelschips (coolships) like foeders are en vogue again after languishing forgotten for centuries. A lot of places are revising this traditional practice and I believe allowing a modern revision of these vessels is long overdue. Coolships were used long before spontaneous beer-making in Belgium. Everyone from English brewers to German brewers literally “cooled” their beer in big shallow open surfaced vessels and a cool night breeze considered enough to do the job before moving the beer into their fermenters.

Plate chillers are a relatively new technology. Before their invention, the simplest way to cool a beer was to spread it out in a wide shallow vessel encouraging a (then) rapid cooling. Unbeknownst to the brewers at the time, this also started introducing their local microbial fauna as well. The Belgians took things a bit further in the ageing and blending process. Thus, gueuze as we know it was born.

Burning Sky Coolship with barrel staves above – photo credit: Good Beer Hunting

Our coolship will have a total volume of 44hL and will perform its practical duties of chilling wort overnight our windows cracked open to the cool Norfolk night air, steam wafting up into the chestnut rafters. Using our local raw wood in the room will allow us to reach back in time through all of the years the wood has grown wild on the estate and taken on local yeasts and bacteria ready to be introduced to our spontaneous beers. The rafters are raw chestnut wood harvested off the estate and seasoned on-site for the 2 years while our project was ongoing.

Coolship brewing is typically only performed in the cooler months likely between November and February. So often this room would just sit empty, which is where I got a little clever about our design. But I’m afraid I’m going to leave it to your guesswork for now and not explain my trade secrets until I’d road-tested my idea behind this dual-purpose vessel. I’ll just leave it to say I wanted to make the coolship earn it’s keep and find a way to get more experimentation going on and more beer out to y’all. Stay tuned.

We asked Sam at 6ix fab dec for comment on making our coolship, here is what he wrote.

“We manufacture a lot of brewhouses at 6ix fab dec, we’ve also modified coolships. It’s great to see less used traditional methods in brewing come back and this was our first start to finish coolship build. Bates came to us with a genius design to give the Duration coolship a twist and a dual function, he’s a bit of a mad scientist in that regard. We jumped at the opportunity to be involved and we can’t wait to see his invention in use”.

“6ix fab dec are thrilled to be supporting Duration a big start up project with ambition and enthusiasm. Brexit has had a huge impact on everyone’s spirits and we need people with a sense of adventure to keep innovating through the flat times. The energy and fresh ideas Duration have to charge forward and make great things happen is refreshing. We hope Duration will lead the industry forward and encourage new growth”.

– Sam Cable, General Manager, 6ix Fab Dec

In our next post, Metal we’ll cover the main brewhouse, where our wort is produced and our clean beer is cellared in our German engineered 20HL 3 vessel brewhouse. We’ll walk you through the whole flow process and share all the shiny toys included our UK first canning line and all the customisations we made.